Keihin provides quality electronic control units for the mobility industry. Our electronic control units implement control strategies that meet increasingly stringent requirements for safety, security, quality and performance. Our dynamic customer focused teams of associates challenge themselves with developing and producing the Electronic Control Units that exhibit high performance and while minimizing cost.

Our electronic control units have been verified and validated for critical embedded control systems for applications such as:

-

Fuel injection and emission controls

-

Automatic transmission controls

-

Gaseous fuels controls

-

Battery control for hybrid and electric vehicles

-

Electric traction motor control for hybrid and electric vehicles

-

Active Mount control

-

All Wheel Drive control

Contact Us

Battery Management System

The battery management system (BMS) detects the quantity of running batteries utilized in full electric and hybrid cars with high-accuracy while also performing the monitoring and control of lithium batteries. The BMS controls charge and discharge, cell balance, high-voltage line connection, and cooling.

Keihin product features

-

Compact, lightweight, low-profile - To achieve durability against excess temperature and vibration in addition to compatibility with the inherent electromagnetic environment in electric vehicles, the enclosure improves the fuel economy and is small, lightweight, and low-profile.

-

Expansion of total battery charge - Incorporation of a cell voltage sensor function allows for improvement of cell voltage detection accuracy. The mounting angle of battery monitoring IC makes this BMS unique. By incorporating unique circuit designs, the overall battery charge is improved.

-

“ISO-26262 ASIL-D" compliant - In compliance with functional safety standards, this reliable system prevents cell overcharge.

-

EMC reliable design - This system effectively reduces electrical noise generation and protects from external electrical noise.

Customer benefits

-

protects the vehicle's lithium battery life

-

improves the vehicle's range

-

compact size

Production base

Management Electronic Control Unit

The management electronic control unit (ECU) calculates the required torque of the electric motor. The calculation is based on the amount of battery charge remaining that is reported by the battery management system and the user's desired accelerating profile. The calculations are supplied to the power control unit (PCU) that drives the motor as instructed while meeting the optimum total energy management in the electric vehicle control system.

Keihin product features

-

Multi-type electronic control unit - This unit is compatible with electric and gasoline vehicles.

-

International standard "ISO-26262" compliant - This unit is developed in a process that complies with the safety standards of the "ISO-26262" function in the electronic and electrical areas of the automobile.

Customer benefits

-

Compatible with various electric vehicle types (battery electric, hybrid, and plug-in hybrid)

-

Global optimum delivery by multiple production sites

Production base

-

USA, Keihin Carolina System Technology

-

China, Dongguan Keihin Auto Electrodeposition Equipment Co., ltd.

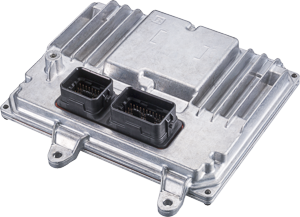

Electronic Control Unit for Automobile

An electronic control unit (ECU) for running overall vehicle functions, this unit detects the conditions of the accelerator and transmission and the environmental conditions, such as temperature and atmospheric pressure, from sensors in the vehicle. The ECU transmits necessary information, such as air requirement, fuel injection amount, and ignition timing, to other peripheral vehicle devices to insure proper operating conditions

Keihin product features

-

Multi-type electronic control unit - By promoting the standardization of the unit package, this unit is a multi-type ECU that can be installed in various engine sizes and types. This includes gasoline direct injection engines and gasoline port injection engines.

-

International standard "ISO-26262" compliant - This unit is developed in a process that complies with the safety standards of the "ISO-26262" function in the electronic and electrical areas of the automobile.

Customer benefits

-

Compatible with various electric vehicle types (including gasoline direct injection engines and gasoline port injection engines)

-

Global optimum delivery by multiple production sites

-

Provides commonality in the verification process of multiple vehicle models

-

Boasts reduced power consumption and size

-

Contributes to improvement of the overall fuel efficiency of vehicles

Production base

-

USA, Keihin Carolina System Technology

-

China, Dongguan Keihin Auto Electrodeposition Equipment Co., LTD.

-

Japan, Miyagi Seisakusho

-

Thailand, Keihin Auto Parts (Thailand) Co., LTD.

-

Indonesia, PT Keihin Indonesia

Electronic Control Unit for Fuel Cell Power Generation Control

The fuel cell (FC) power generation control unit maintains the balance between hydrogen gas and oxygen in the system of a fuel cell vehicle so that the fuel cell can generate electricity efficiently and safely.

Keihin product features

-

Compact size - This unit reduces volume by approximately 40% compared to conventional designs that have similar functions of FC device control and power generation control.

-

Heat dissipation technology - Unique heat dissipative enclosure and optimized control pc board heat transfer through the enclosure fins allows this design to reach heat dissipation that is 70% higher than previous design iterations.

-

“ISO-26262 ASIL-D" compliant - This unit complies with the ISO-26262 functional safety standard

-

EMC reliable design - This unit is designed to effectively reduce electrical noise generation and protect the system from external electrical noise.

Customer benefits

-

Improved FC power generation performance

-

Safety

-

Compact size

-

Allows for more freedom in overall layout and in the layout of the engine compartment

Production base

Electronic Control Unit for Fuel Cell Stack Impedance Measurement

An electronic control unit (ECU) that monitors the impedance of a fuel cell stack so that the amount of moisture contained in the stack can be maintained properly. Keeping the proper moisture content in the FC stack prevents stack deterioration and contributes to longer fuel cell stack life.

Keihin product features

-

Compact size - This unit is optimized to insulate high-voltage functions from low-voltage while simultaneously adding miniaturization and ensuring safety.

-

High-precision stack impedance measurement - High-speed sampling and high-performance EMC filtering technology allow for a highly accurate impedance measurement.

-

EMC reliable design - This unit effectively reduces electrical noise generation and protects the system from external electrical noise.

Customer benefits

-

FC stack life

-

Low-cost

-

Compact size

Production base